A Real-Time Compressed Sensing-Based Platform for Data-Efficient Machine Monitoring

ID# 2021-5326

Technology Summary

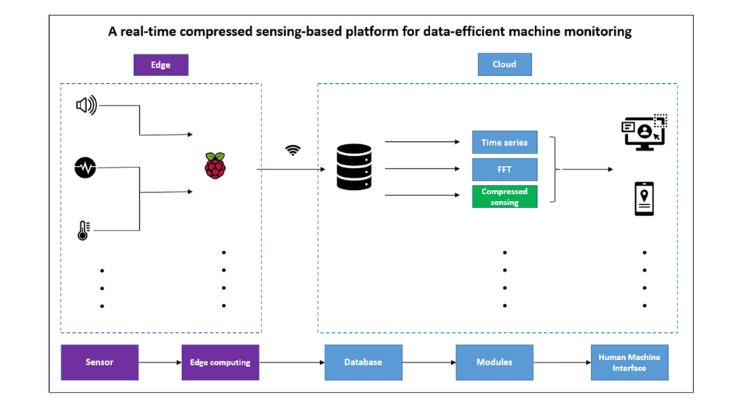

This technology leverages compressed sensing and random sampling to monitor industrial machines using less data than what is used in contemporary data acquisition and analysis. This technique is a combination of novel experimental and data analysis. The building blocks comprise edge computing hardware, software-on-the-edge, and software-on-the-cloud, all written in an open-source language and using COTS-based sensors and single-board computers. Conventional signal processing algorithms are included as modules on the cloud for other data analysis applications.

Application & Market Utility

This innovation solves the problems caused by ‘big data’ in industrial machine monitoring. Through the utilization of novel insights from compressed sensing theory and random sampling, a fraction of all data is used in this technology to reconstruct the original signal (~10-30% for some implementations). This data savings has significant business and engineering benefits, such as savings and cost and complexity of developing and deploying IoT- based sensor systems. Another implementation involves using low-dimensional representations to solve certain types of problems pertinent to machine monitoring. A machine monitoring system (hardware and software) is an example of a product resulting from this technology, which will provide industrial asset insight.

Next Steps

The research team is seeking to further commercialize this technology through licensing and investments.