Extrusion and characterization of compounded recycled polyethylene terephthalate (rPET) filaments for material extrusion additive manufacturing

ID# 2022-5532

Technology Summary

Polyethylene terephthalate (PET) is one of the most used thermoplastics. PET is recyclable, strong, and lightweight, making it an ideal material in the rigid packaging industry. The continuous growth of the annual production and consumption of PET is coincided with increasing waste that leaks into the environment, landfills, and oceans as microplastic and nano plastic fragments. Recycled PET (rPET) has been an inevitable mitigation strategy to combat the concerns of PET waste. rPET experiences properties degradation through the recycling process that reduces/limits its manufacturability into useful products. The development of sustainable rPET filaments to embrace the concept of the circular economy seems to have huge potential in fast-growing additive manufacturing processes.

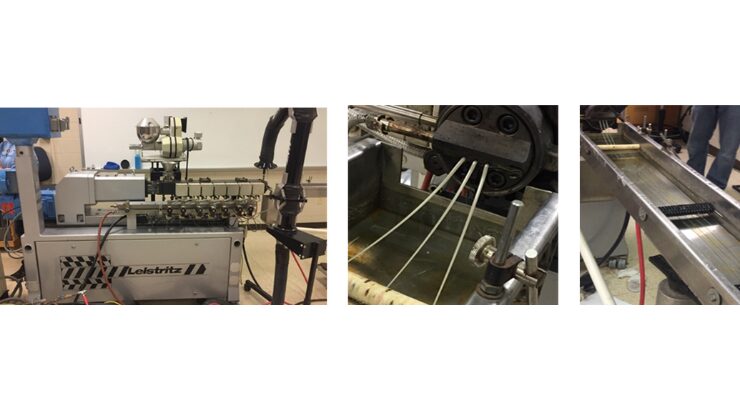

Researchers at Penn State have developed an extrudable filament comprising recycled polyethylene terephthalate (rPET) with low-cost additives, such as a chain extender, toughening agent, reactive impact modifier, and nonreactive impact modifier. Compounding rPET with such additives resulted in a filament that can be used in MEX-AM technologies and that displays advantageous thermal and mechanical properties. Method of making the extrudable filament is further developed as well.

Application & Market Utility

This technology focuses on extrusion of compounded rPET pellets with chain extender and impact modifiers into filament for MEX-AM technology to embrace the concept of circular economy and sustainable materials. Being able to customize the mechanical properties with the utilization of low-cost additives without negatively affecting thermal degradation or requiring more processing steps is advantageous. Many efforts and additives have been investigated and were successful in improving the properties of rPET. This technology addresses rPET’s lack of use as a filament for 3D printing in the global market.

Next Steps

The standard ASTM (American Standards for Testing and Materials) test specimens for mechanical properties were 3D printed, and tested; the test results showed comparable results to the virgin PET. Researchers are seeking licensing and potential research collaborations.