Printable, Programmable Self-Assembled 2D Biocomposites

ID# 2016-4539

Technology Summary

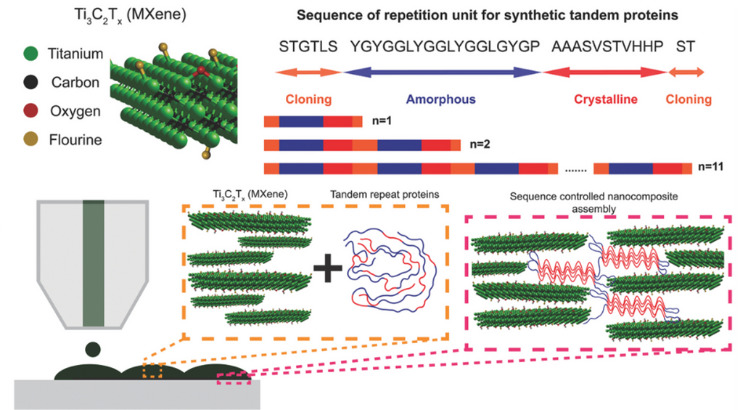

This technology relates to a method of making a biocomposite material comprising 2D inorganic layers (e.g., graphene oxide, titanium carbides, etc.) and polypeptides with alternating repeats of crystalline and amorphous domains. The method involves combining the inorganic materials and polypeptides in an organic solvent and printing them onto a substrate, which results in formation of biocomposite layers comprising the polypeptides and inorganic material. Repeated deposition will result in a multilayered biocomposite. The figure above provides a schematic representation of protein-mediated assembly of titanium carbide sheets during printing, as well as the sensor response of conductive lines with various thicknesses of biocomposite material printed on a PET substrate during humidity cycles alternating between 60 – 70% RH (left), 60 – 80% RH (center), and 60 – 90% RH (right).

Application & Market Utility

This technology enables stimuli-responsive biocomposite electrodes to be printed on various substrates such as paper, glass, and flexible polymers. These electrodes have shown electrical conductivity values that far exceed those of leading inkjet-printed electrodes composed of other 2D materials including graphene and reduced graphene oxide, and this is sustained under excessive bending. These biocomposite electrodes also exhibit effective EMI SE values reaching 50 dB for a film thickness of 1.35 µm. Finally, responsiveness to stimuli other than humidity is being explored.

Next Steps

Seeking investment, licensing opportunities, and/or research collaborations.