Method for Biomimetic Channel-Based Membrane Fabrications

ID# 2018-4770

Technology Summary

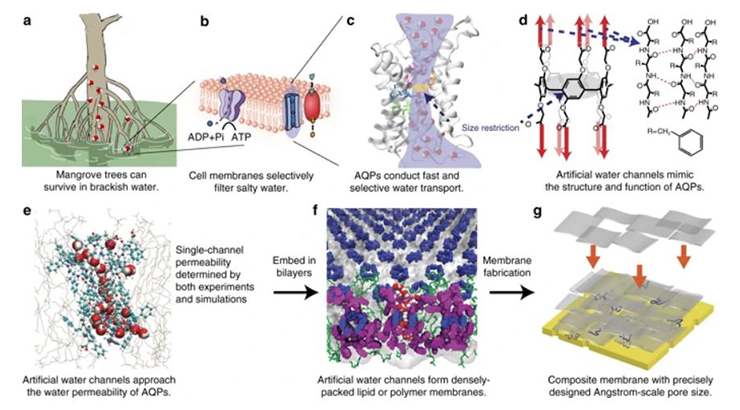

Polymeric membranes designed for angstrom-scale separations, such as water desalination, water purification, and gas separations, are limited by the inherent size distribution of their pores. Nonuniform pore size results in selectivity-permeability trade-offs due to the negative effect of structural variability on solution-diffusion mechanisms. Overcoming this limitation to allow both

high permeability and high selectivity requires membrane fabrication processes that separate the diffusion-pathway elements from the matrix element, such that highly uniform diffusion elements can be incorporated into the non-uniform polymeric matrix.

This Penn State team has developed a membrane fabrication process that incorporates a highly uniform artificial water channel, pillar[5]arene, into a block copolymer membrane matrix.

Application & Market Utility

The resulting bioinspired membrane is highly selective with a molecular weight cutoff of approximately 500 Da, while maintaining an order of magnitude higher permeability relative to commercially available membranes. At their core, the membranes are composed of microscale 2D composites which are assembled layer-by-layer to achieve 100% coverage of the substrate. The membrane fabrication process and layer-by-layer assembly enables enhanced channel density and scalability without any detrimental effects.

Next Steps

Demonstration of the membranes and the fabrication process is available. Currently seeking a commercial licensing partner.