Cold Sintering Process for Powdered Metals

ID# 2018-4818

Technology Summary

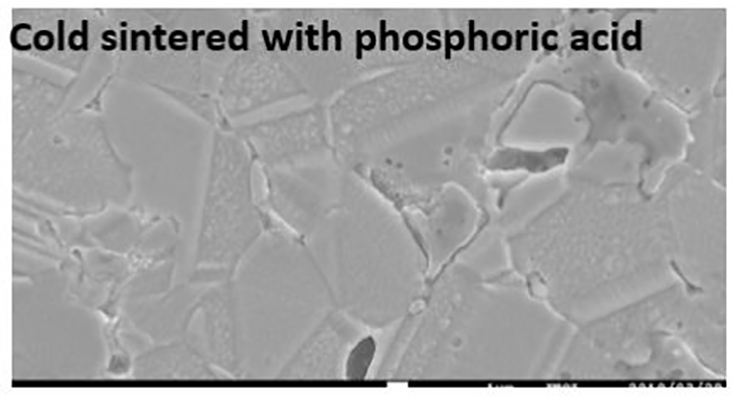

The well established manufacturing process of powder metallurgy involves the sintering of pressed powder metal parts to metal components of desired shape and size with close tolerances. Such tolerances are contingent upon green densities as close to 100% of theoretical density. Traditional compaction methods typically have relative densities of about 88% – 92%.

Application & Market Utility

The invention’s unique process at relatively modest temperatures of 100°C – 150°C with a compaction time of 60 min or less yields up to ninety-five percent (95%) density. The inventors have reduced the invention to practice in a range of powder systems, including copper, iron, nickel, steel, tantalum, stainless steel and brass as well as potentially other metals and their alloys. Results show commercially meaningful increases in Vickers and Rockwell hardness compared to traditional sintering at temperatures over 700°C.

Next Steps

The inventors have produced 3mm – 50 mm diameter sintered metal parts with 7 -8 mm thickness with improved hardness. The inventors are making larger prototypes and anticipate potential applications within automotive, aerospace and medical devices.