Two-stage System for Cellulosic Biomethane Production

ID# 2021-5265 and 2021-5266

Technology Summary

The invention utilizes two sequential digestion reactions. The first reaction digests lignocellulosic feed at an alkaline pH and thermophilic temperature to produce a high purity biogas as well as digestate rich in volatile fatty acids. This digestate is then exposed to a neutralized pH and produces a second biogas that improves the overall yield. This second stage promotes the conversion of additional lignocellulosic feedstock and soluble intermediates (e.g. the suite of volatile fatty acids produced in the first alkaline digester) to further produce methane and carbon dioxide.

Application & Market Utility

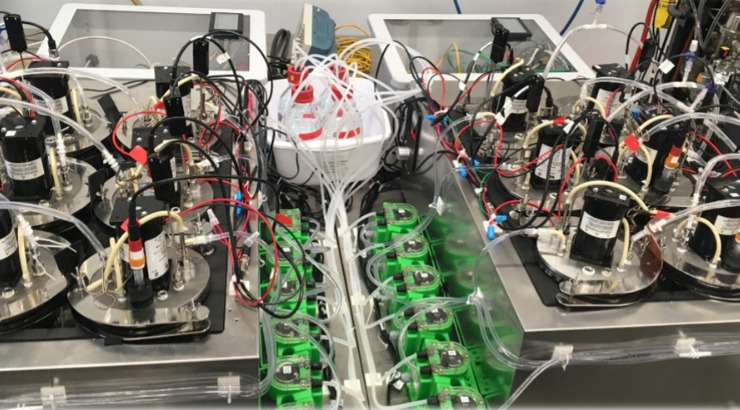

This system using small reactors of two-liters or less yields a carbohydrate conversion that is as much as 1.5 times greater than any other known condition for anaerobic digestion of untreated senescent switchgrass (feedstock). At steady-state the first stage alkaline reaction produces high purity biogas at greater than 89 volume percent methane compared with conventional anaerobic digestion, which averages around 60 volume percent. The higher the methane produced, the lower the separation costs to increase the purity level to RNG levels (i.e. >97 vol% methane).

Next Steps

Scale-up requires larger reactors and milling machines to prepare the cellulosic feedstock. The capitalization costs of scale up is a barrier to entry though the RNG purity allows for use of existing pipelines.