On-Demand Thermal Curing of Polymers for 3D Printing

ID# 2016-4509

Technology Summary

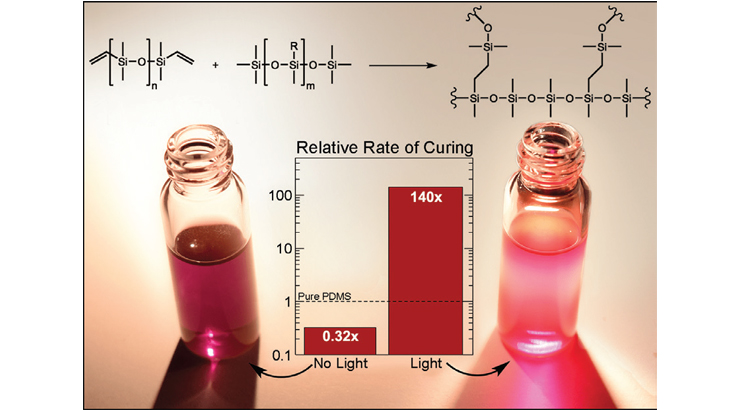

Because of slow time scales associated with bulk heating/cooling, it’s hard to stop the thermal curing of polymers using traditional approaches. Elevated levels of bulk-scale temperatures drive unwanted side reactions, limiting the temperatures for use and the rates of curing, making use of thermally cured polymers for 3D printing difficult. The Lear Laboratory provides on-demand thermal curing of polymer systems using nanoscale materials to efficiently convert light to heat. The light-to-heat conversion results in extreme temperatures near the nanoscale materials, which greatly enhances the rate of polymerization. The technology achieves billion-fold enhancements of polymerization rates while preserving desired chemical control over the final products.

Application & Market Utility

This technology provides on-demand, nanosecond control over the start/stop of the reaction and allows for reactions at much higher temperatures, allowing greater rates of polymerization. Applications include on-demand curing of coatings for technological applications and 3D printing.

Next Steps

Seeking research collaboration and licensing opportunities.