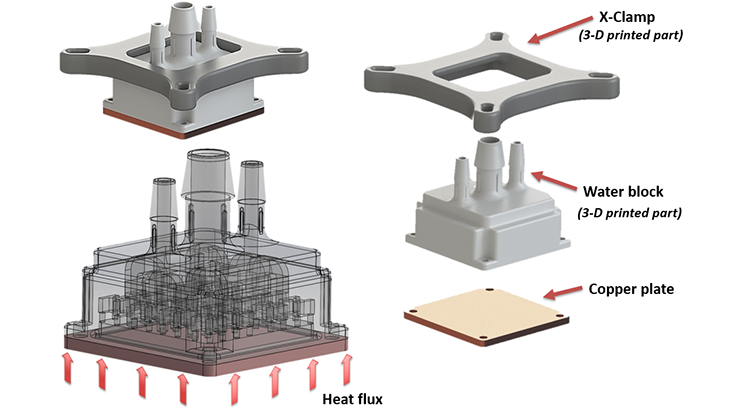

Hybrid Microjet Liquid-Cooled Heat Spreader

ID# 2018-4854

Technology Summary

The research team has developed a novel liquid-cooled heat sink design. The water block has a large inlet duct connected to a resin shell. Inside the shell, a fractal manifold divides the inlet coolant flow into several substreams that eventually exit in the form of uniformly distributed liquid jets through small nozzles at the bottom of the shell. The union between the shell and the copper plate forms a thin flood chamber, where the jets impinge on the copper plate, dissipating the heat supplied to the copper plate in contact with a heat source. The warm liquid is removed from the device through a secondary manifold embedded within the resin shell, where the exit holes alternate the inlet jet nozzles on the bottom of the shell. The warm fluid exits the water block through two outlet channels after the exit manifold has merged the several exit substreams from the flood chamber.

Application & Market Utility

The experimental tests of these heat sinks are promising, as a difference of 3°C is observed when compared to state-of-the-art liquid cooled heat sinks made in their entirety of copper. Since this technology utilizes a resin shell, the amount of copper required is less, resulting in similar (or better) cooling performance at a significantly lower cost to manufacture.

Next Steps

The technology is patent-pending. The research team seeks collaboration for future development and licensing.