3D Printing Geopolymer Structures Having a Lower Ecological Footprint

ID# 2017-4699

Technology Summary

The conventional geopolymer is produced through a chemical reaction between high alkaline solution (sodium silicate solution) and aluminosilicate precursor (fly ash or metakaolin). The disclosed invention, MarsCrete, has been designed to be activated just with water without the need for alkaline solution. As the alkaline solution is mostly corrosive, it makes the bulk production of geopolymer difficult and limits the application of geopolymer in the construction, but present novel binder can easily be used in large construction in the field.

Application & Market Utility

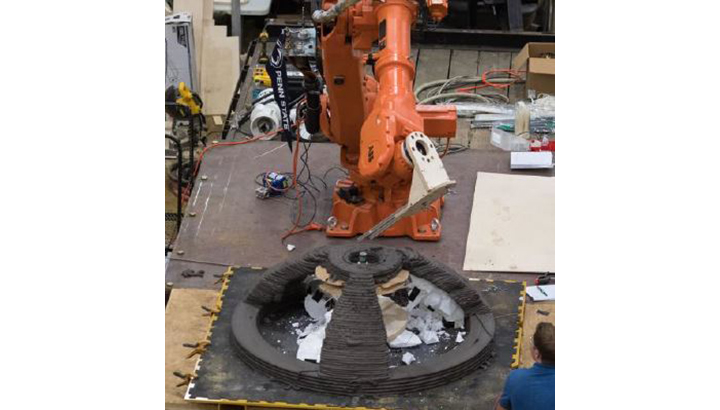

MarsCrete is 3D-printable and has been used in large quantities for the NASA 3D-Printed Mars Habitat Challenge; it met all of the mechanical property requirements when tested using the ASTM standards and procedures. This composite material has a lower ecological footprint using only 1.6 wt% of Portland cement, which during production releases equal weight of CO2 in the atmosphere.

Next Steps

Conduct fruther fine tuning to control the 3D-printing and setting of the material. Seeking collaboration and licensing opportunities.