Broadband and Omnidirectional Polymer Antireflection Coatings

ID# 2016-4516

Technology Summary

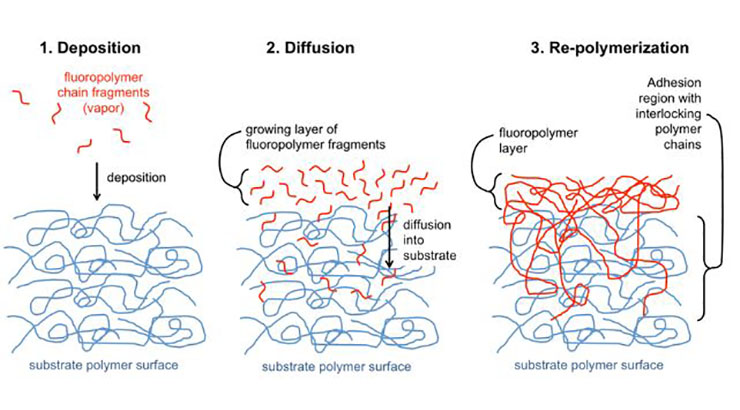

Penn State researchers have developed novel methods of applying an anti-reflection Teflon® coating to polymeric substrates. A salient feature of this technology is its outstanding ability to adhere to the surface of plastics. The researchers created strong adhesion properties by cleaving the coating material into molecular fragments. As a result, the molecular fragments of the coating material diffuse into the polymer substrate’s surface and then re-polymerized in interlocking fashion with the polymer chains of the polymer substrate at the surface of the substrate to be coated with the coating. This re-polymerization process provides interlocking with the substrate polymer chains to deliver an adhesion that is not possible for any other known coatings for plastics to date.

Application & Market Utility

The Teflon® coating can be applied to optical lenses, windows, TVs, computer screens, displays, photovoltaic/optoelectronic devices, or any plastic surface. The coating is compatible with plastic optics, abrasion-resistant, and stable in long-term UV & outdoor. The invention makes displays with higher contrast & lower glare, cameras with higher light transmission, and more efficient photovoltaic panels. Using the developed coating, reflectivity of Plexiglas® is reduced to <1% over the entire visible and near-IR spectral range for a wide range of incidence angles.

Next Steps

Seeking research collaboration and licensing opportunities.