Cement and Water-Free Concrete Using Recycled Plastic Binder

ID# 2023-5594

Technology Summary

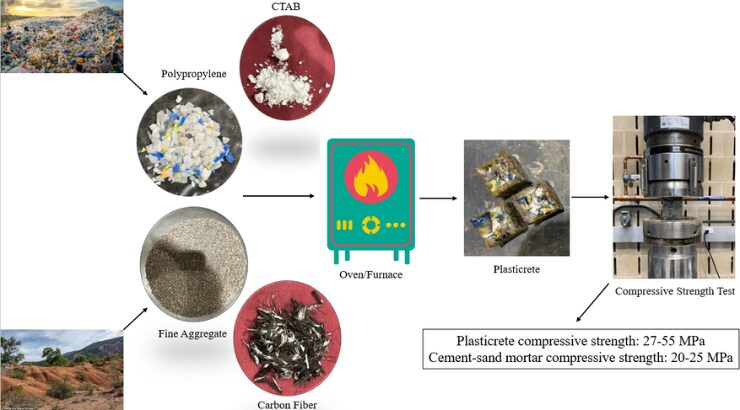

The invention covers a novel concrete production method by incorporating plastic waste into concrete to enhance properties, improve durability, and promote recycling. Studies indicate that substituting up to 10% of sand in concrete mixtures with solid plastic waste maintains compressive strength. Novel waste plastic-based concrete formulations, where plastic waste replaces cement as a binder, exhibit improved mechanical and thermal properties, enhanced durability, reduced weight, and lowered cost – all achieved without the addition of water during production.

This invention provides practical guidelines for incorporating waste plastic into concrete production, offering an optimal mix design using a specific plastic type, plastic-to-sand percentage, and sand particle size.

Application & Market Utility

Globally, concrete stands as the second-most utilized material following water, boasting an annual production nearing ten billion tons. Yet, traditional concrete production exacts significant environmental tolls, marked by elevated energy consumption, greenhouse gas emissions, and resource depletion. Concurrently, the pervasive issue of plastic waste, a prominent environmental threat, contributes to pollution and enduring ecological harm. Addressing these issues necessitates sustainable alternatives to conventional concrete and waste management strategies.

Next Steps

Feasibility of incorporating waste plastic into construction applications in making paving blocks, concrete masonry units, composites for floor tiles, and mortar with plastic waste binder construction material.