Cold Sintering Process for the Sodium Beta Alumina Solid Electrolyte

ID# 2021-5268

Technology Summary

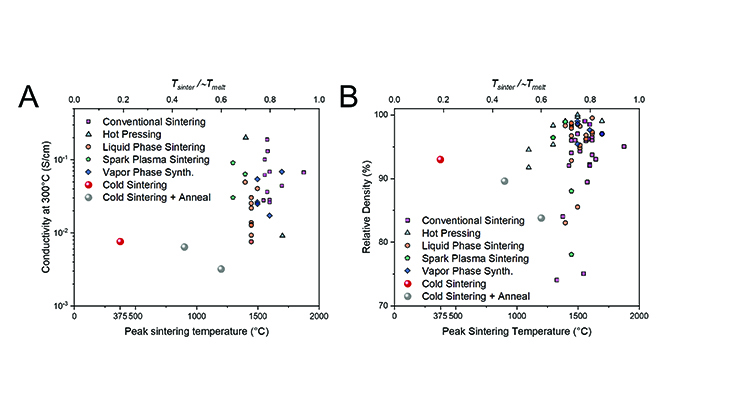

SBA electrolytes are used for high temperature (>200oC) batteries. An adaption of the cold sintering (CS) process produces remarkably dense microstructures of B” SBA at less than 400oC within a three hour dwell time and surpassing ninety percent of SBA’s theoretical density. In addition to no significant porosity in the bulk microstructure, the results indicate very little, if any, B’ SBA is generated by the CS process. The sintered grains are approximately the same dimensions as the original powder, implying a lack of grain growth, thereby avoiding the exaggerated grain growth caused by conventional sintering. The ionic conductivity is competitive with conventionially fired polycrystalline ceramics at high temperature. Annealing of the CS SBA removed impurities such as carbonates and water, thereby improving the low temperatures electrical properties.

Application & Market Utility

Conventionally sintered SBA requires densification temperatures at or above 1600oC. In addition to reduced energy consumption, the cold sintered SBA may find applications in nascent energy storage technologies which need a stable solid electrolyte. The renormalization of the SBA sintering temperature from 80% of Tm to 20% of Tm may present new opportunities for co-processing this historically refractory solid electrolyte with thermally fragile electrodes for next-generation sodium-ion based energy storage technologies.

Next Steps

Scaling up sample size and making thinner samples