Electrically Assisted Metal Forming Process

ID# 2006-3280

Technology Summary

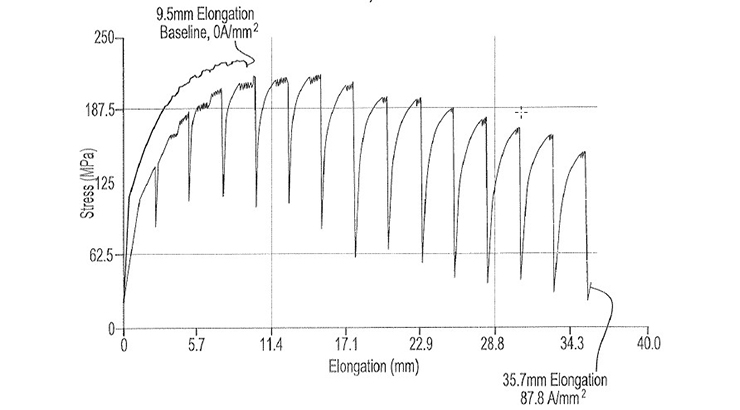

The present invention relates to a method and apparatus for forming a sheet metal blank, a tubular blank, or a partially formed blank while pulses of current are applied, improving formability. Electrodes are attached to a forming tool to provide pulses of current which pass through at least a portion of the blank. The flow of current during a manufacturing process reduces the required deformation energy, improves part quality, and extends the range of manufacturing for a given workpiece material. Benefits of the process include reduced post deformation spring-back, increased workability, and increased tooling life. Application of electricity will improve the operations of sheet metal forming/stamping, forging, extrusion, drawing, rolling, cutting and machining.

Application & Market Utility

The extent by which metal parts may be formed by deforming metal sheets or tubular blanks is limited by the strength and the inherent formability of the metal. Complex parts with pronounced recesses/protrusions may not be formed from a single blank and may require forming multiple parts separately before joining them together. There is a need for a method and apparatus for forming extensively formed parts made in a single piece that are plastically deformable to the maximum extent.

Next Steps

U.S. patent 7,516,640 has been issued. Proof of concept verified; further concept development ongoing. Seeking licensing opportunities.