Electrically Assisted Single-Point Incremental Forming

ID# 2008-3484

Technology Summary

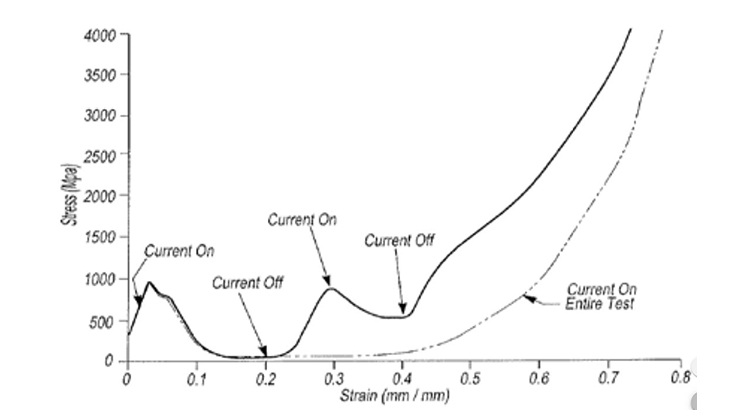

Single-Point Incremental Forming (SPIF) is a technique for forming 3D sculptured sheet material parts. This die-less fabrication technique forms parts from flat sheet metal by lowering a spherical tool into the material slightly, causing permanent deformation around tool tip. A programmed tool path is then where the sheet metal is plastically deformed as the tool traverses the material. This disclosed application improves on existing technologies by applying electricity to SPIF to increase material formability and reduce spring-back. Research shows applying electricity to traditional die-based sheet metal deformation processes significantly increases the ability to deform materials without tearing the sheet stock or elevating temperature. In this invention, more isolated electricity is applied by having the electrical current flow down the SPIF spherical tool and onto the work piece.

Application & Market Utility

Localizing electricity allows for significantly lower currents to be applied to the area where deformation is to occur. Because electricity has been shown to allow stored elastic energy to be converted to permanent plastic deformation, this invention reduces spring-back after the tooling tip has traversed the material, increasing part accuracy and reducing the number of passes required to indent the desired deformation, thereby increasing the potential production rate of the SPIF process.

Next Steps

Further testing on commercial products. Seeking licensing and commercialization.