Fracture Conductivity Tuning Technique to Improve Heat Extraction in Enhanced Geothermal Systems

ID# 2022-5501

Technology Summary

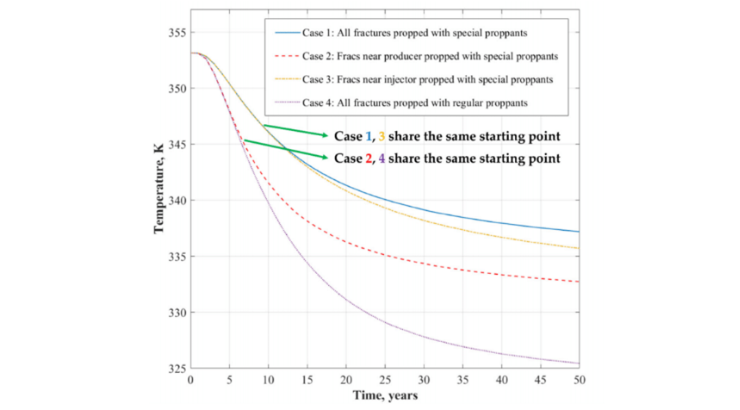

Penn State researchers developed a 3D mathematical model optimizing EGS performance using a Fracture Conductivity Tuning Technique (FCTT). This technique can be used to increase heat extracted from a reservoir over its’ lifetime by increasing fracture hydraulic conductivity (FHC) in high temperature zones and decreasing FHC in low temperature zones of a reservoir, thereby preventing early thermal breakthrough to a production well. FCTT is based on use of special proppants, either on their own or in combination, with regular proppants with temperature sensitive solubility designed to optimize heat flow/temperature of produced fluids over time. The special proppants are coated with a resin which can deform with temperatures thereby adjusting FHC; at high temperatures the proppant retains its original unexpanded shape, at lower temperatures they expand diminishing FHC. Simulations indicated that use of the FCTT over a 50-year period improved cumulative heat extraction by at least 39% in a geothermal reservoir by increasing the temperature of the produced fluid.

Application & Market Utility

- Increasing geothermal power production through design of more efficient subsurface fracture networks.

- Development of more effective subsurface heat flow geometries in a geothermal reservoir.

- The geothermal energy market was valued at $6.6 billion in 2021 and is expected to reach $9.4 billion by 2027 at a CAGR of 5.9%

- Increased electricity demand using sustainable energy sources is the major factor driving growth.

Next Steps

Seeking licensing and research collaboration opportunities.