Friction Stir Additive Manufacturing Billet and Tube Production

ID# 2017-4641

Technology Summary

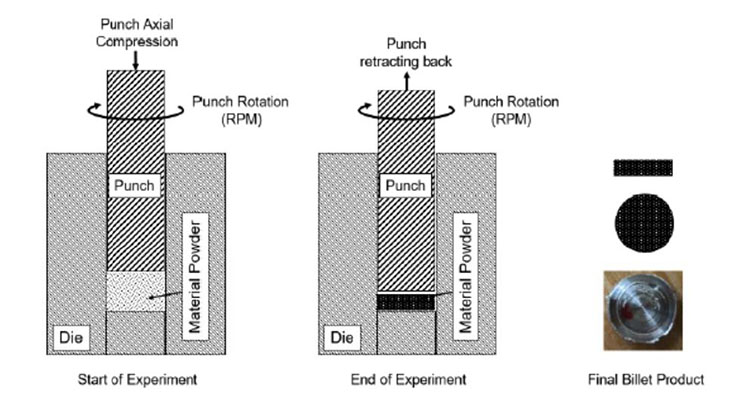

The invention relates to friction stir welding techniques that use aluminum powder (or other metal powders) to generate metal workpieces in the form of billets, tubes, pallets, wires, sheets, or plates. Such workpieces can be used as building blocks for metal parts in various machines, tools, etc. A workpiece is manufactured by inserting metal powder into a die, wherein a punch (e.g. friction stir head) processes the powder by compression and rotation. As a result, a green compact is generated and subsequently sintered within the die. The green compact formation and sintering process forms a billet as the punch is retracted. The figure above illustrates this process, which can be repeated to form additional layers. Embodiments include a continuous billet forming process and a process that generates tube products.

Application & Market Utility

These techniques allow for various shapes and sizes of a workpiece to be generated in the form of blanks, billets, or tubes. The workpieces can be incorporated into parts used in the architecture, aerospace, automotive, furniture, or jewelry industries.

Next Steps

Seeking research collaboration and licensing opportunities.