Gas Mixing using High-Speed Valves

ID# 2016-4438

Technology Summary

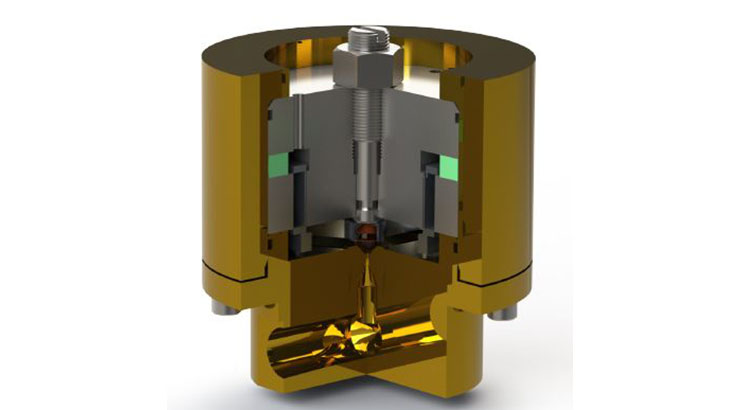

The present invention pertains to a switched nozzle valve (SNV) that regulates gas flow. By using a converging-diverging nozzle, the SNV achieves constant flow when the valve is on. The geometries responsible for regulating the flow are precisely machined, and are not required to change for the valve to operate. Since the flow rate while on is constant, the effective flow through the valve is adjusted by varying how long the nozzle is left open for each cycle. If the switching frequency is sufficiently fast, then the dynamics of the line carrying gas from the valve will tend to smooth the flow into the time average of the pulse-width-modulated flow in the nozzle. This approach results in a gas flow control system somewhat analogous to a switching power supply.

Application & Market Utility

Computer numerical control (CNC) plasma cutting systems are of commercial interest because such systems allow for gas flow rates and the selection of gases to be digitally specified. However, most systems use choked orifices (valves with no pressure) to regulate flow of gases making CNC systems economically inefficient. The present invention is a substantial improvement in applications requiring digital control of gas regulation such as plasma cutting or even welding processes. Relevant industries include fabrication, automotive, salvage & scrapping, and construction.

Next Steps

A prototype has already been successfully made and tests have showed a constant delivery flow rate. The profile of the valve’s flow response to its electrical command has been verified. Currently seeking industry partner for commercialization.