Graded Index Inorganic Antireflection Coatings Produced by Magnetron Sputtering

ID# 2022-5422

Technology Summary

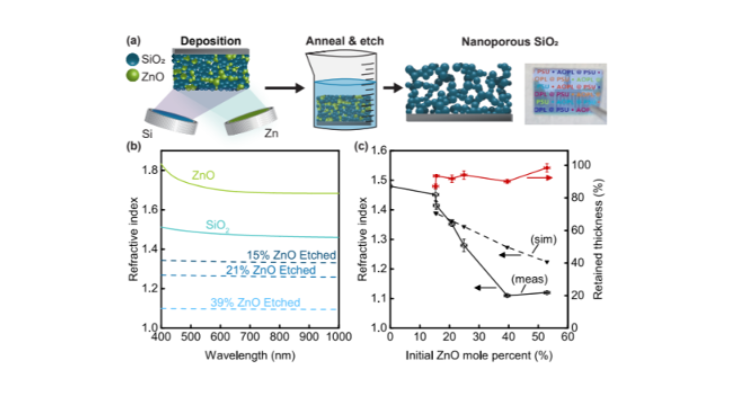

This invention covers the fabrication of nanoporous multilayer silica thin films via magnetron sputtering for antireflection coating applications. Briefly, silica and another material such as ZnO are co-sputtered together to form a mixed film, annealed to induce phase segregation, and then the ZnO is dissolved away in a dilute acid solution to leave behind a nanoporous silica scaffold. The ability to control nanoporosity (and therefore the refractive index) with nanometer precision enables ultrahigh performance antireflection coatings to be fabricated.

Application & Market Utility

The current techniques for fabricating graded-index multilayer antireflection (AR) are not economical and cannot be scaled to large areas. This invention provides the material composition and process to enable the fabrication of these coatings via magnetron sputtering, which coats millions of square meters of display and low-e glass every year. This approach demonstrated a step-graded bilayer AR coating with outstanding wide-angle AR performance (average reflectivity in the visible spectrum ranges from 0.1% at normal incidence to 0.9% at 40°), good adhesion, and promising environmental durability. These results open a path to realize ultrahigh-performance AR coatings over large areas using an industrial-scale magnetron sputtering system.

Next Steps

Seeking collaboration and potential licensing opportunities.