Improved Vise for Contouring to Irregularly Shaped Components

ID# 2017-PSSHE-26

Technology Summary

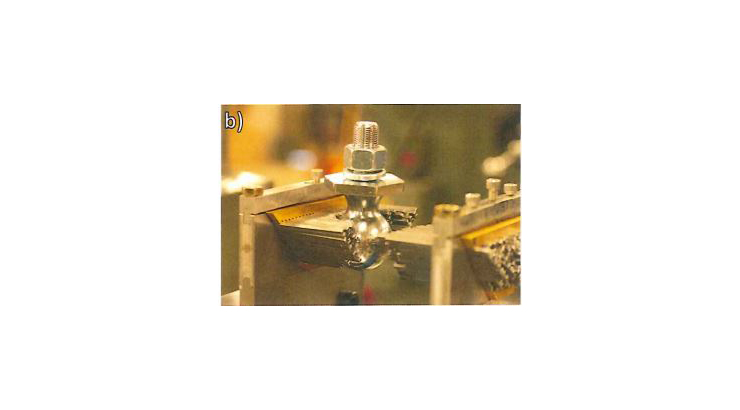

The disclosed invention describes a vice or work holding technology that uses an array of pins to shape to parts with high complexity. The design is meant to mimic the operation of pin art toys, creating a custom fit around and within the part features. A pair of plates resting on a mounting plate form a frame in which the array of pins are held. An adjustable insert sits atop the pins and beneath the top of the frame. A force is applied to the insert to clamp down on the pins. The pins are configured to be held by compressive force and the resulting friction created by their intimate contact. Pins of different lengths, thickness, and shapes can be exchanged through a simple process.

Application & Market Utility

-Replaces the costly, timely process of casting a jaw to fit a specific design

-Pins are quickly reset to fit a regularly changing design

-Pins can act as a loading surface for elevating a part orf holding flat parts at a desired angle

-Found to be more resistant to an applied torque on a spherical part than flat jaws or V-blocks

-Acts as a cost-effective mold for replicating parts where surface detail is negligible

-Alternative method for filling volume in the shipping and packaging industry

Next Steps

Prototype verified; seeking licensing opportunities.