Improving graphitic quality by oxidative liberation of crosslinks in non-graphitizable carbons

ID# 2022-5475

Technology Summary

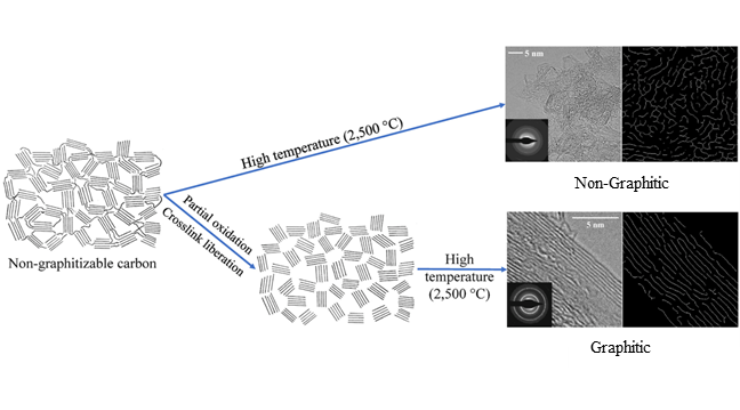

Graphitization is the process of thermally converting amorphous carbon into graphitic carbon. Traditional conditions are energy-demanding, requiring temperatures in excess of 2500 °C. Recent efforts have been devoted to the development of greener routes using lower temperatures or waste as a carbon source in order to be more sustainable. Many amorphous carbon sources form non-graphitizable structures due to crosslinking. For many of these materials, crosslink removal would greatly improve the graphitic quality after graphitization. Researchers at Penn State have developed a method of partially oxidizing carbon materials to effectively remove graphitization-inhibiting crosslinks. Removal of the crosslinks leads to better stacking of the graphene planes and can potentially increase the electrical conductivity at a lower mass loading.

Application & Market Utility

The worldwide production of graphite in 2023 was close to 1.3 million metric tons. Graphitizable precursors are the basis for synthetic graphite manufacture. This technology will facilitate the use of cheap and renewable precursors to create high-value carbon materials for applications such as lubricants, batteries, fuel cells and friction materials.

Next Steps

This process has been demonstrated on carbon black and a non-graphitizable sugar char. These examples can be expanded to other sources such as carbons derived from resins or lignocellulosic materials.