In-Situ Monitoring for PBFAM Using Multi-Modal Sensor Data Fusion

ID# 2019-0951

Technology Summary

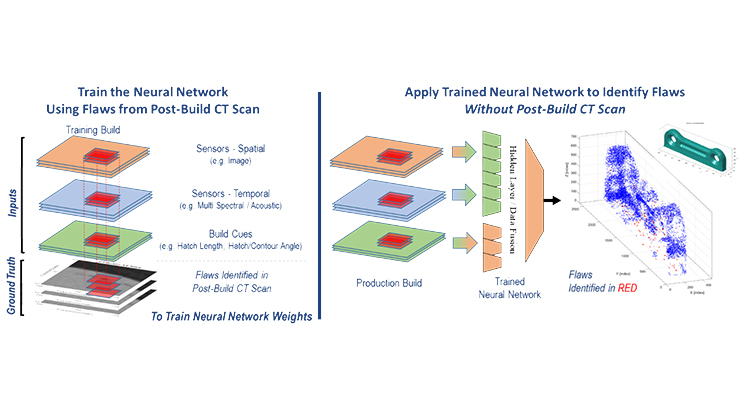

This technology offers in-situ process monitoring capabilities for Powder Bed Fusion Additive Manufacturing (PBFAM) processes. Real-time, multi-modal sensor data, such as camera imagery as well as acoustic and multi-spectral emissions, are acquired in the build chamber and subsequently fused to generate a coherent footprint of the underlying process. Sensor fusion entails several preprocessing and registration strategies to align all sensor data in the time and spatial domains. Machine learning techniques have been used to correlate anomalies in the data stream to actual physical defects, identified via post-build Computed Tomography (CT) scans.

Application & Market Utility

This technology addresses the need for defect detection in additive manufacturing. Long build times means that defects discovered after the assembly of a part is completed has significant impact. The ability to detect defects in-situ provides an opportunity to correct defects during the build process, allowing for significantly greater acceptance of completed objects due to being defect free.

Next Steps

The research team seeks collaboration and licensing opportunities.