Multi-spectral Method for Powder Bed Fusion Additive Manufacturing

ID# 2017-0934

Technology Summary

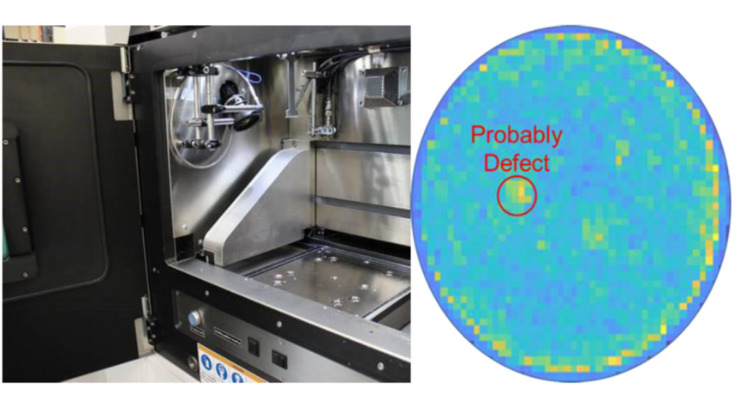

A multi-spectral sensor system has been developed that allows for real-time, in-situ (as opposed to post-build) defect detection in parts formed from powder bed fusion additive manufacturing (PBFAM). Build quality is assessed by measuring the line-to-continuum ratio of Chromium (Cr I) emission lines around 520 nm and continuum emission around 530 nm from a melt pool and plume during the build process. The emissions are indicative of defects (e.g. lack of fusion and porosity) within a part. For example, build quality can be measured as percentage of voids within the part. Test results indicate that a higher magnitude spectral response is correlated to a higher percent void.

Application & Market Utility

This technology allows for the discovery of defects within powder bed fusion additive manufacturing parts in real time, before a part has been completed. Therefore, the invention is applicable to all parts made through the powder bed fusion additive manufacturing process. Accordingly, this technology will make possible the identification of components’ suspected build quality and potential flaw locations to guide post-build inspection, decreasing cost and increasing consumer confidence in the process.

Next Steps

Seeking research collaboration and licensing opportunities.