Novel Method for Microwave Processing Using Highly Absorbing Pastes

ID# 1998-2042

Technology Summary

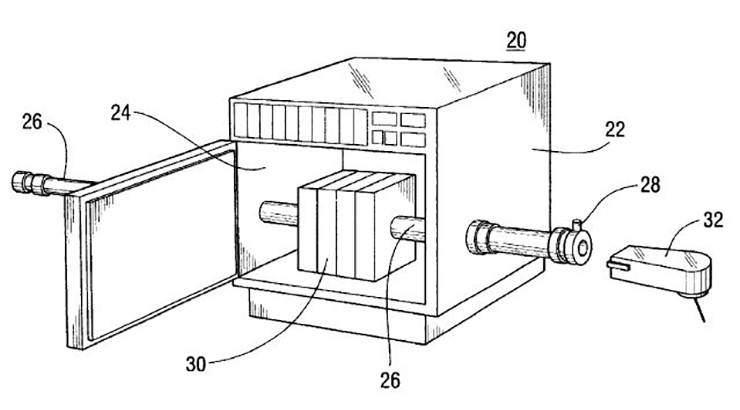

Microwave processing is superior to conventional processing owing to its rapidity, simplicity, energy and time saving capabilities. Ceramic materials do not couple well with microwave radiation at low temperatures, therefore they need to be preheated by another heating source. The use of secondary microwave susceptors as a packed bed around the ceramic to be processed has often been used as this preheating source.

For its secondary susceptor, the present microwave method uses a 2 mil thick coating of microwave absorbing carbon paste prepared from graphite and water, The pasta is applied around insulating containers such as a ceramic tube or crucible made from Silica, Alumina, Zirconia, or Mullite. The material to be processed is then housed in the coated ceramic container and exposed to the microwaves.

Application & Market Utility

This hybrid heating methodology allows one to rapidly synthesize, sinter or melt ceramics, glasses, composites, inter metallic alloys, and powdered metals. The carbon coating can be applied on materials of any complicated shape. The carbon coating is superior to commonly used SiC or MoSi2 secondary microwave susceptors. The use of SiC or MoSi2 rods are limited by slow heating rates and high expense. The new microwave method using carbon coating as a susceptor is much faster, simpler, cheaper and more energy efficient.

Next Steps

Regular patent (6,512,216) issued on 1/28/2003. Seeking licensing opportunities.