Process for Production of Graphene/Silicon Carbide Ceramic Composites

ID# 2012-3972

Technology Summary

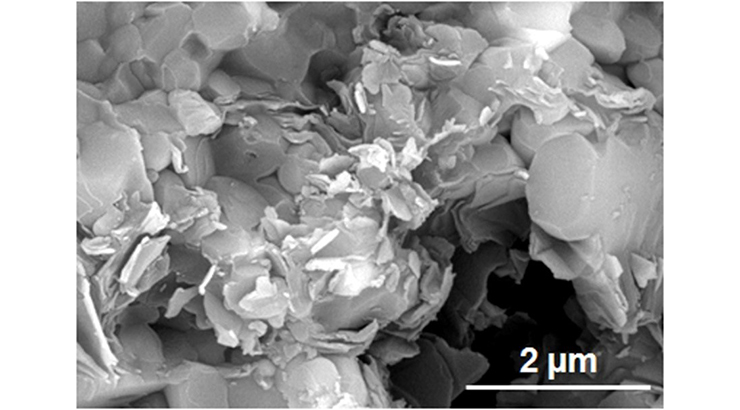

This single-step process makes in-situ graphene containing silicon carbide (SiC) matrix ceramic composites with extensive graphene growth within the SiC matrix. This approach allows for processing dense, robust, highly electrical conducting, tough and well dispersed nanocomposites having a percolated graphene network, while potentially eliminating the handling of potentially hazardous nanostructures. The simplicity and speed of this process eliminates certain production costs, while improving yields. While demonstrating a range of physical strength between 300-1000 MPa for these novel, homogenous graphene/SiC nanocomposites, the graphene’s electrical conductivity is nine orders of magnitude higher than the electrical conductivity of graphene free SiC ceramics with similar amount and type of sintering additives.

Application & Market Utility

SiC ceramics exhibit excellent thermal and high temperature mechanical properties suitable for a wide range of structural applications. The addition of graphene as filler further enhances those properties, including outstanding tribological and electrical performance. Graphene/SiC components could be used in technological applications under strong, demanding conditions where good electrical, thermal, mechanical and/or tribological properties are required, such as micro and nanoelectromechanical systems (MEMS and NEMS), sensors, actuators, heat exchangers, breaks, components for engines, armours, cutting tools, microturbines ro microrotors.

Next Steps

Sample evaluations by prospective materials manufacturign licensees and/or application end users