Salt-Ceramic Composites and Manufacture Thereof

ID# 2018-4721

Technology Summary

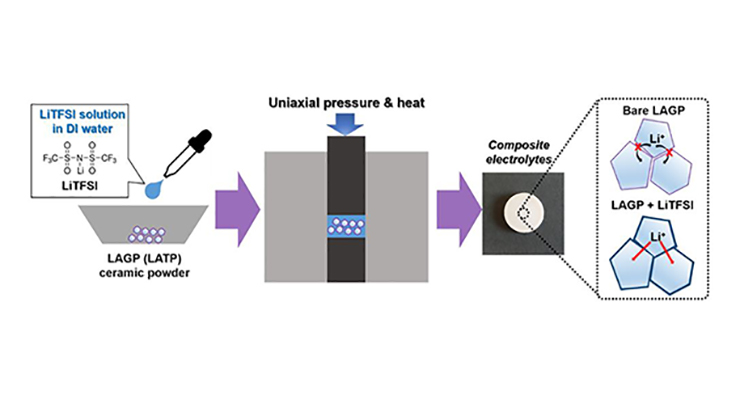

A novel, highly dense salt-ceramic composite electrolyte prepared by a Cold Sintering Process (CSP) at low temperatures (below 200 degrees Celsius) has been developed. The obtained sigma (s) values were almost identical with solid lithium electrolytes conventionally sintered above 800 degrees Celsius, though with greatly reduced grain boundary resistance with the addition of a dopant. The CSP materials had preserved NASICON-type hexagonal crystal structures with no increase in the amount of impurity phase. The invention’s materials can be cycled in excess of 0.2 mAh/cm2. The voltage profile was very stable over 500 hours suggesting no dendrite formation.

Application & Market Utility

The inventors have developed a simple process to sinter monolithic ceramics, multilayer structures, flexible printed structures and composites as low as 100oC. The CSP composites result in well-compacted pellets that are easy to handle. Results also demonstrate relative density (87%-over 90%), conductivity, and maximum density (> 10-4S/cm at RT) as compared against the same materials conventionally sintered. The novel, high modulus, non-flammable/non-combustible composites have potential use as a solid ion conductor in batteries.

Next Steps

Seeking research collaboration and licensing opportunities.