Die Reduces Springback in Sheet Metal Forming

ID# 2013-4046

Technology Summary

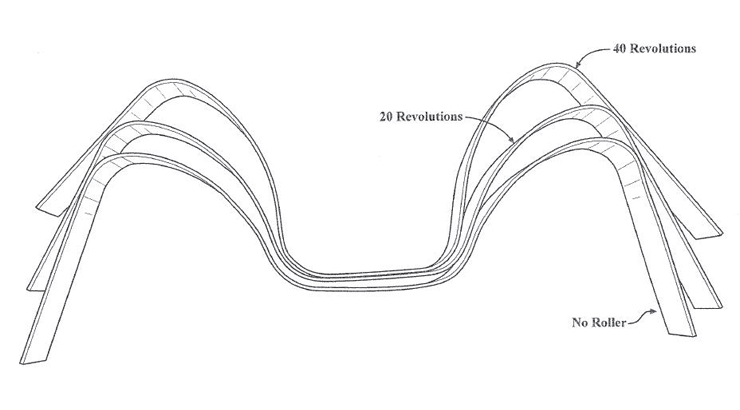

Springback is a common phenomenon that occurs in sheet metal forming when metal is bent but then springs partially back toward its original shape, thus requiring corrections to be made. This sheet metal forming device and process reduces or eliminates springback. The device is a die tool and roller that rotates relative to the die during and/or after forming a piece of sheet metal. The rotation of the roller can be either freely occurring during the forming process or forcibly imposed during and/or after the forming process.

Application & Market Utility

Current methods for dealing with the varying amount of springback exhibited by different materials have proven unsuitable in certain situations, making desirable an improved forming process and/or die for sheet metal forming. This new technology provides an accurate solution that can create significant savings in time invested in making corrections. The tool and process are applicable to all material-forming situations in which the material is pushed or stretched over a corner, including all metal forming (mainly sheet metal forming).

Next Steps

Seeking research collaboration and licensing opportunities.